The concept for “bypass cooling” has been around for years, and it usually comes up here in this BB forum about once a year. I’m not a fan of the idea. Let me explain...

First, what is "Bypass Cooling"? The 6.2/6.5 cylinder heads are interchangeable right for left. Among other features, this provides a convenient coolant port with a block-off plate at the inside rear of each right & left cylinder head. GM produced a somewhat different block-off plate (pn-14028949) for use with their 6.2L diesel engine. These 6.2L block-off plates incorporate a 1/2" NPT pipe thread fitting, which was used for a Glow Inhibit switch on the passenger side cylinder head and for the 1982-83 screw-in glow controller located at the rear of the driver's side cylinder head.

Some feel these 6.2L block-off plates could be installed on a 6.5L diesel, and would provide a good place to mount a pair of 1/2" hose barbs to pull coolant out of the head, and re-route that coolant to somewhere near the thermostat housing. The arrangement allows a portion of the coolant to "bypass" traveling through the cylinder head. Some have installed such a modification and saw a reduction in engine coolant temperature, as seen by the engine coolant temperature sensor located in the coolant crossover at the front of the engine near the thermostat housing. This is a problem. If the coolant isn't picking up as much heat in the heads as it should, of course, the ECT (engine coolant temperature) sensor will report a decrease.

GM’s “6.2 Liter Diesel Engine” product service training manual #16015.05-1D says this about the Cooling System Schematic.

“Coolant is drawn from the lower radiator hose by the water pump. The pump pushes coolant into both sides of the cylinder block. Coolant flows around the cylinders and up into the heads, where it circulates around the exhaust passages and fire deck areas, then flows forward toward the thermostat housing.”

For the following images and discussion, let's assume we're looking at the passenger (right) side of the engine.

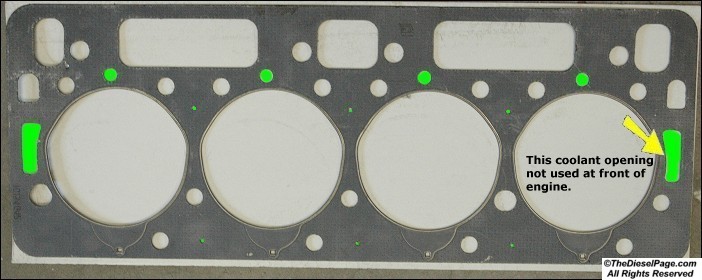

This head gasket image shows the ports (highlighted in green) where coolant can pass from the block, through the gasket, and up into the heads. The rectangular passage shown on the right is not used at the front of the engine (ahead of cyl 2 on the right bank, ahead of cyl 1 on the left bank). The cylinder block does not contain a coolant passage at that location.

The rectangular coolant port on each head gasket (behind cyl #8 on the right bank & behind cyl #7 on the left bank) each passes approximately 50% of the coolant flow for that side of the engine, which then travels forward through the heads. The remaining 50% of the head coolant flow comes from the other smaller round ports in the gasket – again, highlighted in green.

There are a series of tiny holes in the head gasket (green dots) that allow a small fraction of the coolant to pass into each head, which are there primarily to allow trapped air and steam to escape.

Head gaskets used on the 6.2/6.5 are identical for both right & left banks. If the above cylinder head was to be installed on the passenger side of the engine, only those coolant passages outlined in red are allowing coolant to pass from the block and into the head.

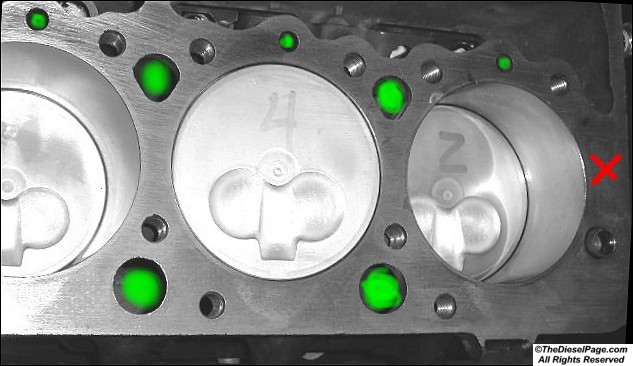

This photo shows the front portion of the passenger side block deck. Cylinder #2 is at the right side of the photo. You can see that there is no rectangular coolant passage matching the head gasket (red X).

I believe most people who think taking coolant out at the back of the heads improves engine cooling come to that conclusion after seeing the several large coolant passages in both the block and head decks. Problem is, most of them are blocked off by the head gasket. Those large passages are there to facilitate manufacturing the sand-cast heads & blocks.

This photo shows the passenger side block deck cylinders #6 & #8. The larger rectangular cooling passage is behind cylinder #8, which matches the port in the head gasket. Some of you have noticed the scored cylinder wall in cylinder #6, and have asked how that occurred. I used this photo primarily to show the cooling passages, but that picture does have a story... The condition of #6 (and #5 on the opposite bank) was the result of 1500 degrees EGT and 250 degrees engine coolant temperature. As you can see, high coolant temperatures do not always affect the rearmost cylinders, which is an argument used by those who promote bypass cooling.

In conclusion: Taking coolant out at the back of the heads reduces the amount of coolant flowing forward and through the heads - plain and simple. That cannot be argued. The cylinder heads generate most of the heat in a running engine, and the cooling system has to move enough coolant through them to prevent damage. If a bypass cooling strategy is used, you may see a lower engine coolant temperature, which is what you'd expect if the coolant isn't picking up as much heat as it should in the cylinder heads. Not removing heat from the cylinder heads could result in hot spots that develop in the area around the exhaust valves and exhaust runners, which won’t be reflected by the engine temperature sensor. I’m open to third party data and test results, but till then my opinion is that bypass cooling may actually contribute to cylinder head cracking - engine damage...

Jim

Reply With Quote

Reply With Quote . But then again, I knew better.

. But then again, I knew better. Excellent writeup. You really did your homework here! No bypass BS for me...

Excellent writeup. You really did your homework here! No bypass BS for me...