-

18:1 Compression Ratio

18:1 Compression Ratio

This short tech piece first appeared in The Diesel Page in 1999.

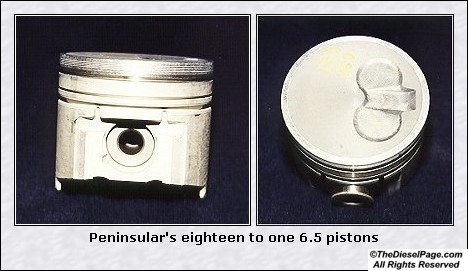

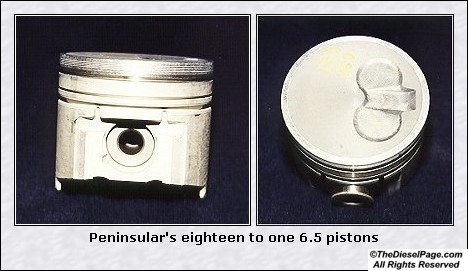

The 18:1 Peninsular pistons were incorporated into our project 6.5TD engine build in late 1998. The advantages of a lower compression ratio (in the context of the project engine) is, a lower CR allows for more boost, and more boost allows for more fuel, which means the engine will make more power, while maintaining reasonable combustion temperatures & pressures. The folks at Peninsular Diesel told me they use a lower CR for the durability advantage.

In 1997, Kevin Emery (part owner of Peninsular Diesel at the time) told me that during engine dyno tests they found that a 6.5TD equipped with the factory 21.3:1 CR would suffer piston failure when run at rated power for about 3 hours. Installing 18:1 pistons would allow the 6.5 to run at rated power indefinitely.

I've always wondered why a lower CR improved durability. Now I know...... I read an analysis in the Turbo Diesel Register recently concerning compression ratios that finally put it all together and explained why a lower CR does what it does.

In issue twenty three (winter 1999) issue of the Turbo Diesel Register, columnist and automotive journalist Kevin Cameron discussed what effect compression ratios have on diesel engine design and efficiency. Cameron's column focused on the "law of diminishing return" and how that is applied to engine design in general, and to compression ratios in particular. Cameron explained that efficiency increases as compression ratios increase, to a point (of diminishing return), then other less desirable side effects become an issue. One paragraph I found particularly interesting is where he said;

- "But there's another effect to consider here, which redoubles the law of diminishing returns. That is overall heat loss (amount of heat that needs to be dissipated) during combustion. As we raise the compression ratio, we also raise the peak flame temperature, and that pushes heat through the head and piston crowns faster. A couple paragraphs ago, we made a curve of theoretical energy recovery versus compression ratio - and how this heat loss effect causes that curve to flatten out even faster. The result is, that for diesel engines, that peak efficiency comes somewhere pretty close to 17 to one compression."

Kevin Cameron TDR

So now, it all comes together. A lower CR lowers the peak flame temperature, reducing the heat load on the pistons and cylinder heads. Voila, improved durability!

Cameron also explained that an indirect injected engine (like the 6.2/6.5), with its added surface area of the IDI pre-chamber, will dampen the heating of the compressed fuel/air mixture during the compression stroke, thus affecting cold starting with a theoretical most-efficient 17:1 CR. He went on to say that most IDI diesels use a 20:1 or higher CR to offset this cooling effect and allow reliable cold starts. Not surprisingly, beginning in the 1997 model year, the L65 6.5 turbo diesels were equipped with 20.2:1 pistons, and the newest 1999 model L65 pistons were scheduled to be reduced further to 19.5:1 (which didn't occur because the 6.5L diesel was dropped from the engine option list in the new GMT-800 new Silverado body style trucks). The first L65 6.5TD engines ran with 21.3:1 pistons. The use of lower CR pistons (20.2:1) is GM's attempt to strike a balance between cold starting ease, glow cycle times and engine durability - for the masses.

Last edited by More Power; 11-16-2007 at 23:13.

Reason: add to

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Reply With Quote

Reply With Quote