Hi everyone!

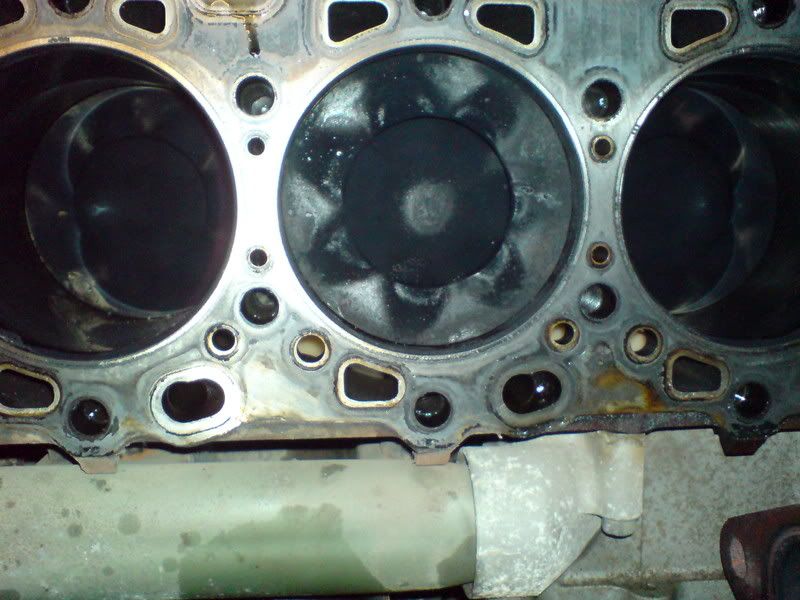

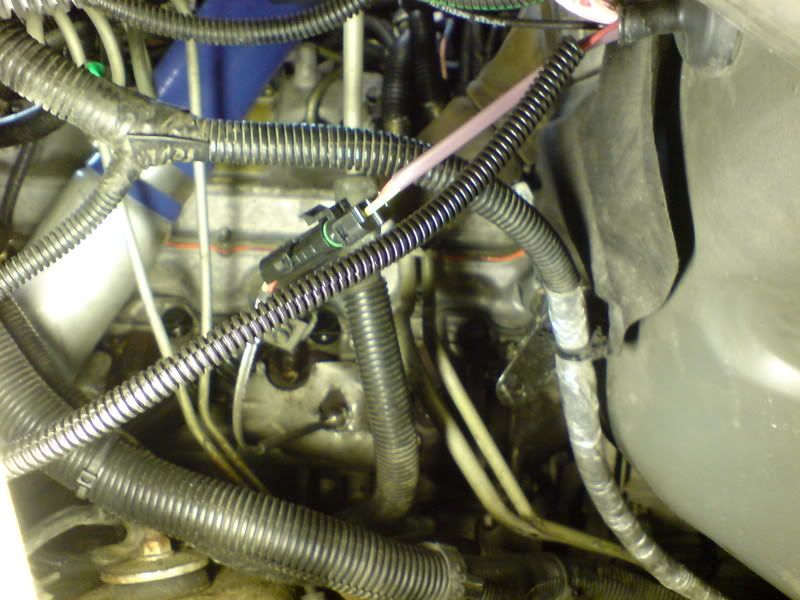

I'm a 22 year old diesel-freak and live in a nice country called Sweden and have recently bought a GMC from a dealer in Indiana (but the trucks first and only owner in US lives in Florida), it's not my first US-truck but definitly the best one, it's in a real good condition expect a "little" engine problem.. i have a coolant leak into one cylinder but it will soon be fixed! and then i hope i can get some trouble free years in the future, i have read a lot positive stuff about the D/A so there's still some hope leftWhat worries me the most is the CAN-bus system, i'm afraid of electronics, it can eat my wallet up at any time.

I work as a Welder and i'm doing TIG-welding in aluminium, copper and stainless steel. On my spare time i'm mostly reading workshop manuals and learning how stuff works, i have specialized my self in Air conditioning- i have built my own AC-systems on a previous car.

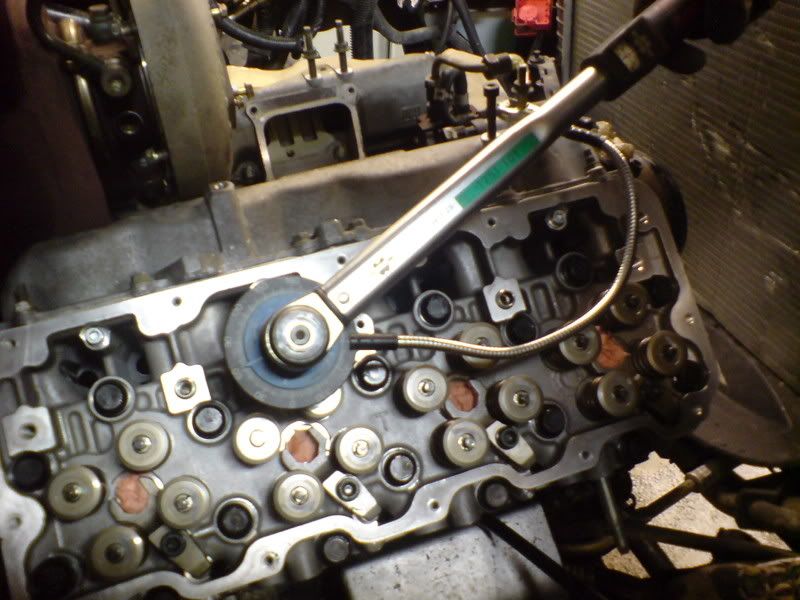

I have rebuilt a couple of automatic transmissions and my latest project was to re-route the oil channels in my Volvo's transmission so that the Lockup works on other gears than just 4:th, and i customized the shift firmness by adjusting oil flow to the acumulators. i called Swedens biggest transmission shop and they had never made any mods more than installing shift kits so i saw it as a challenge.

i have also done some a large home electrical project in my parents house, and a lot of electrical stuff in my vehicles, so i'm very familiar with ohm's law, amperes, volts, hertz, µF, 3-phase theory, magnetic fields etc etc..

Well, i'll end here even though i could write some more but it will just be boring to read, so now i'll show some pic's of my truck!

i have just got it registrated here and i must say that the registration number i got was really funny, but it won't be easy to live up to it!

comments are welcome!

Regards

/Oskar

Reply With Quote

Reply With Quote

i made a headgasket change on my previous K10 6.2D and it took 8 hours to do both sides including oil change and AC recharge!

i made a headgasket change on my previous K10 6.2D and it took 8 hours to do both sides including oil change and AC recharge!