It’s getting cold out and I am too lazy to clean the wood stove chimney in the shop so I fired up the old kerosine heater.

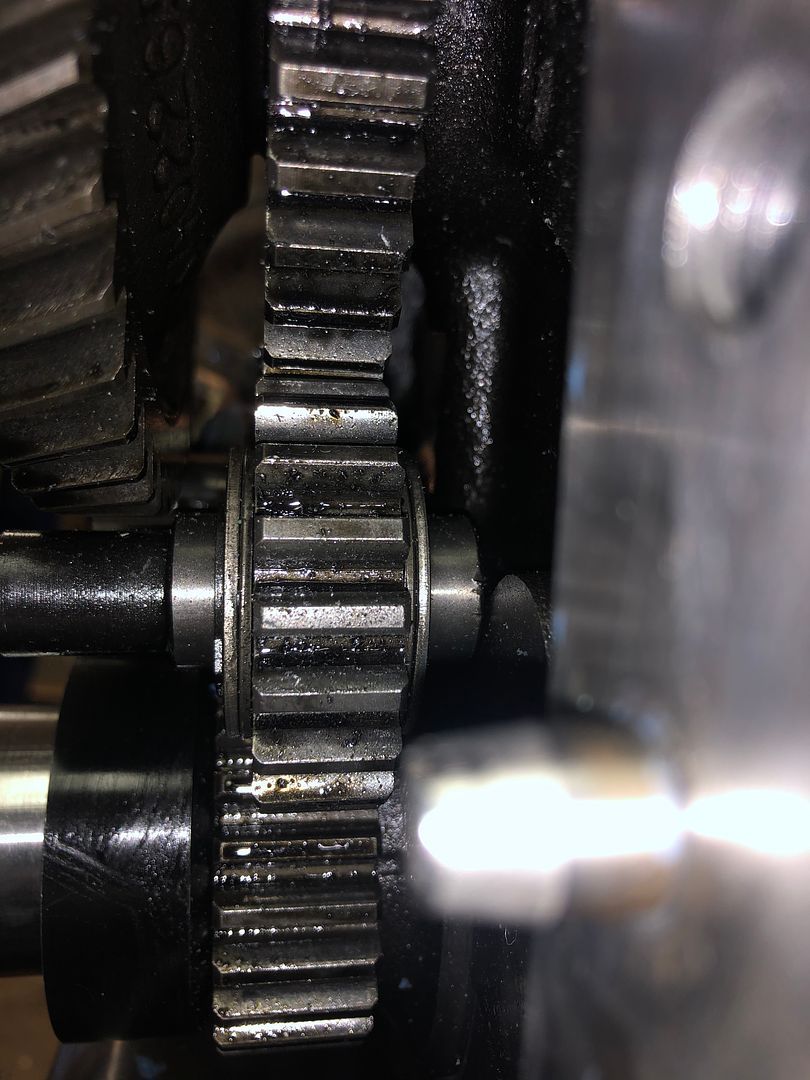

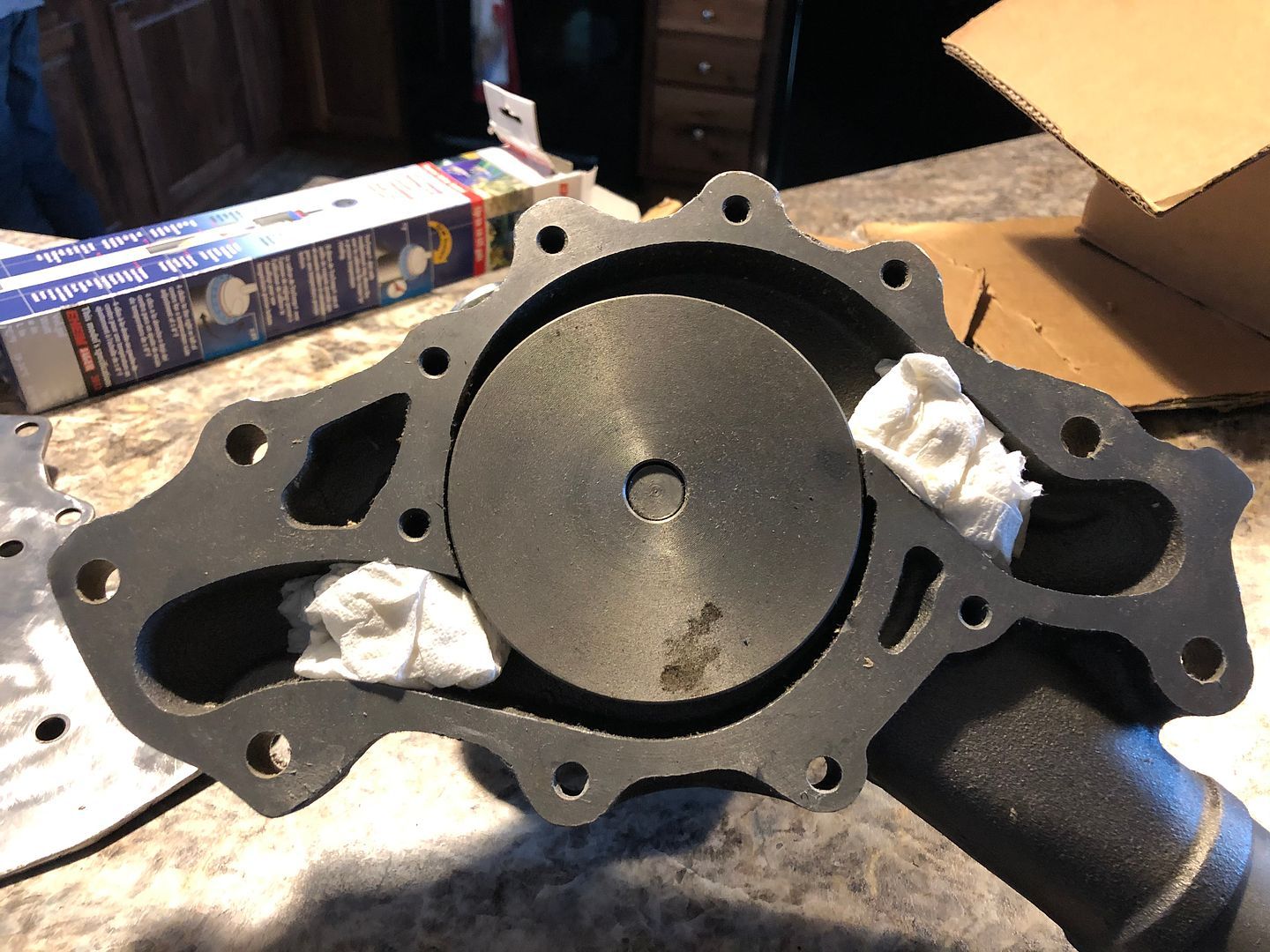

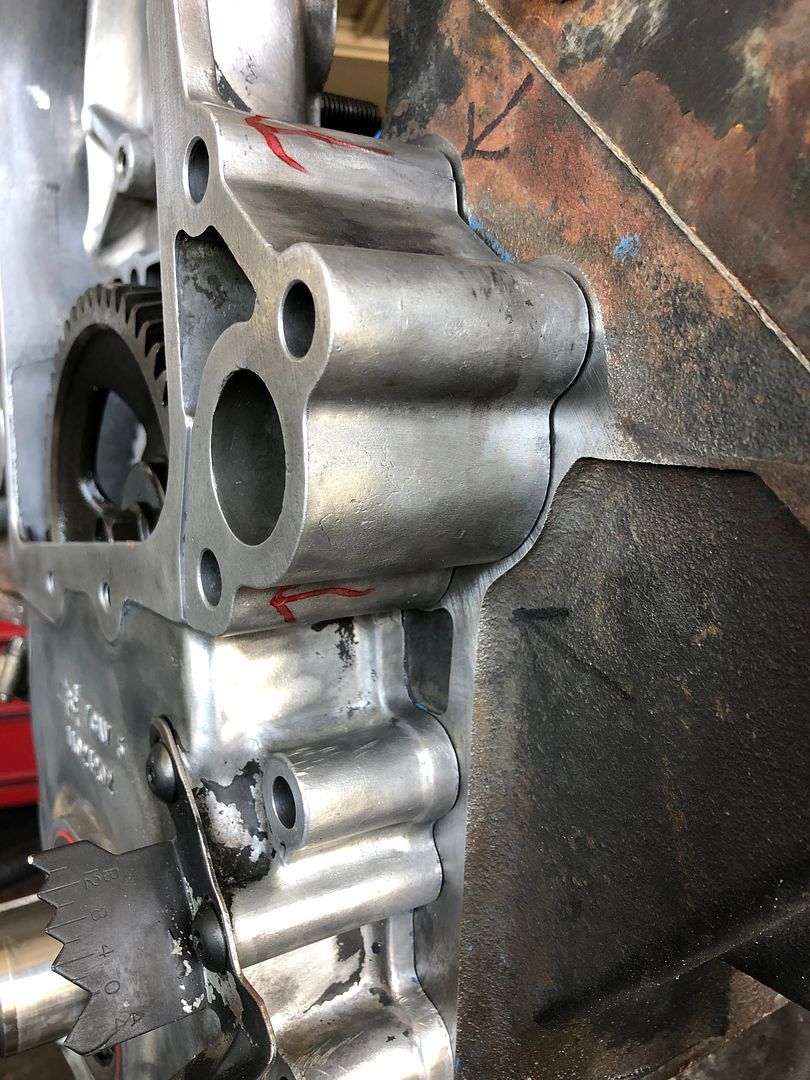

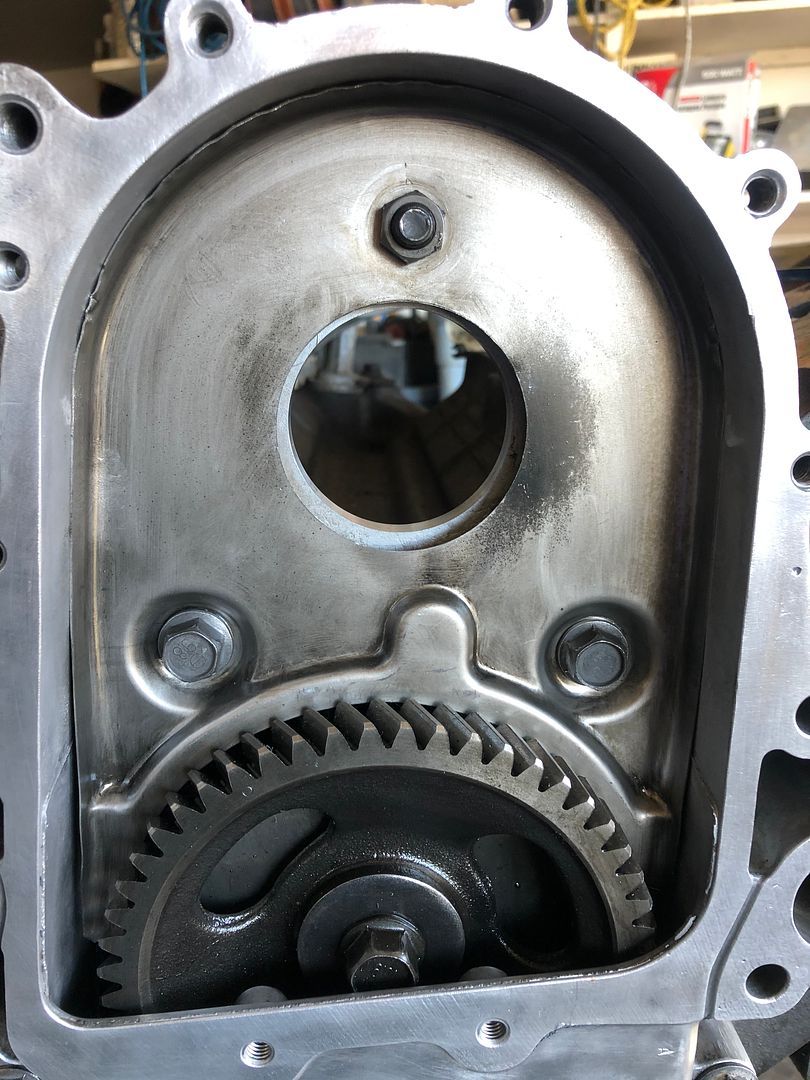

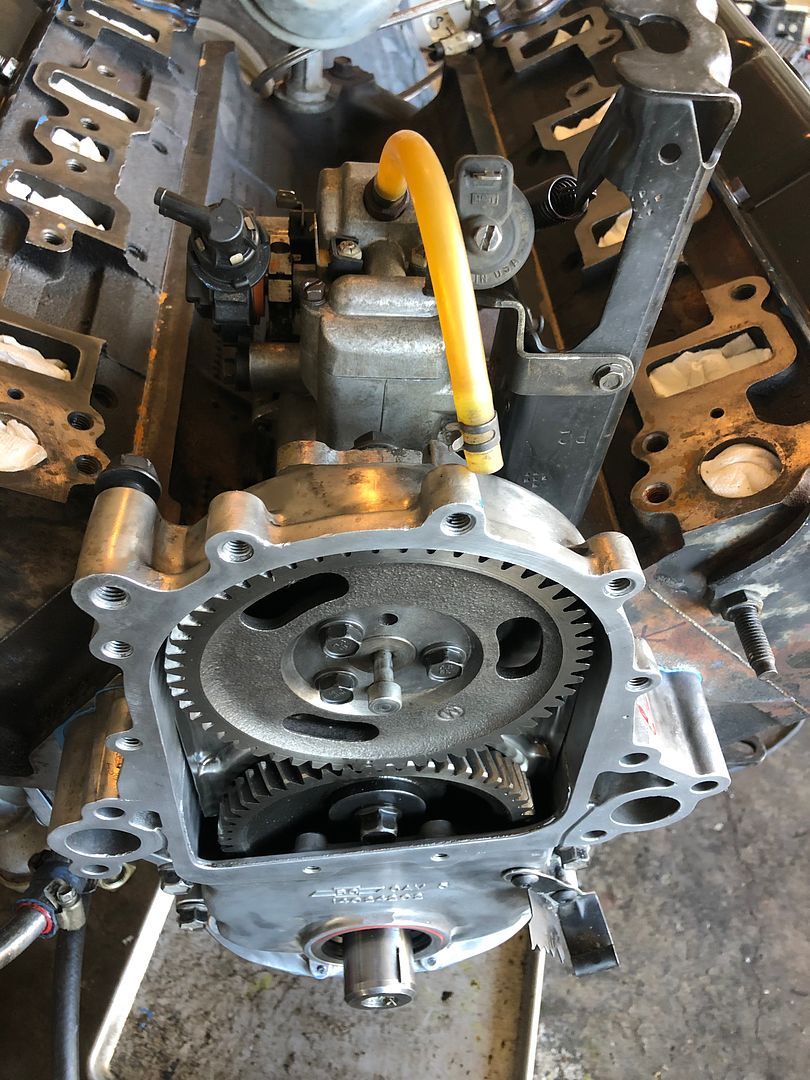

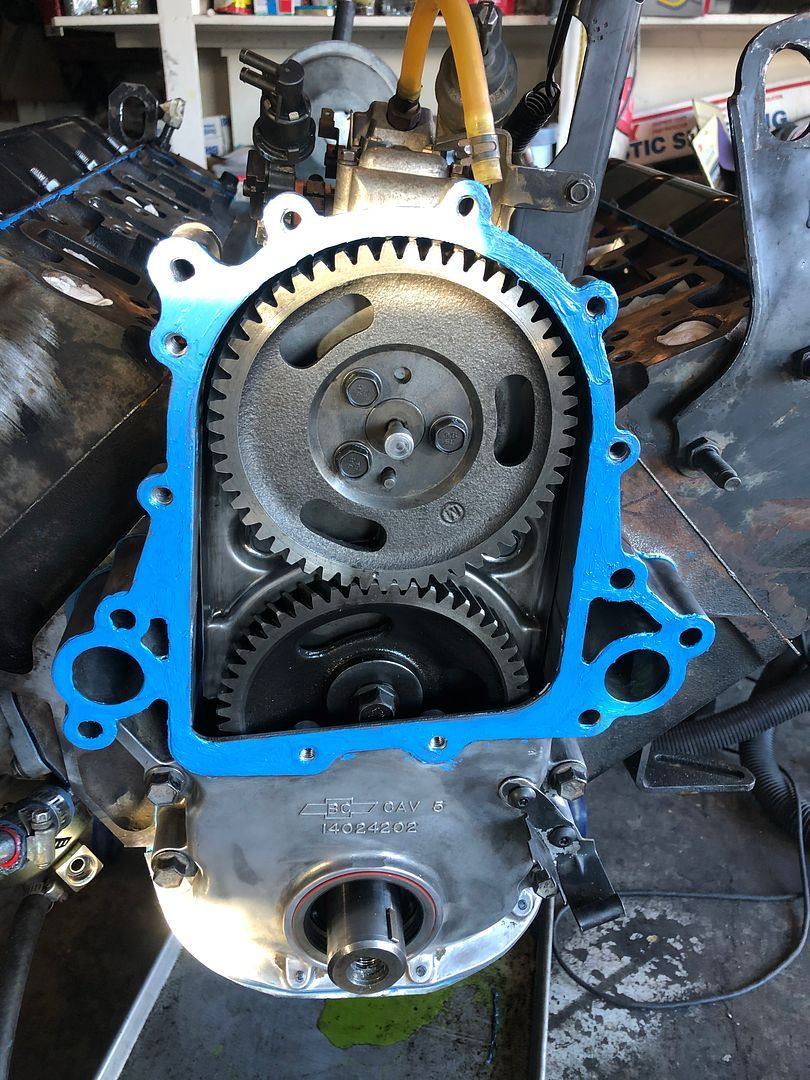

To clean up the old gasket material from the timing plate block side, I used my razor blade and scraped all big pieces of the old gasket off without scratching the surface. Next I used a 120 grit Roloc disk. It felt more like 200 grit. Before doing any work on it, I put a paper towel down and shaped it like a bowl so it would collect any debris preventing chunks falling into the oil pan.

I used the scotch pad to clean areas that the roloc disk was not able to get to.

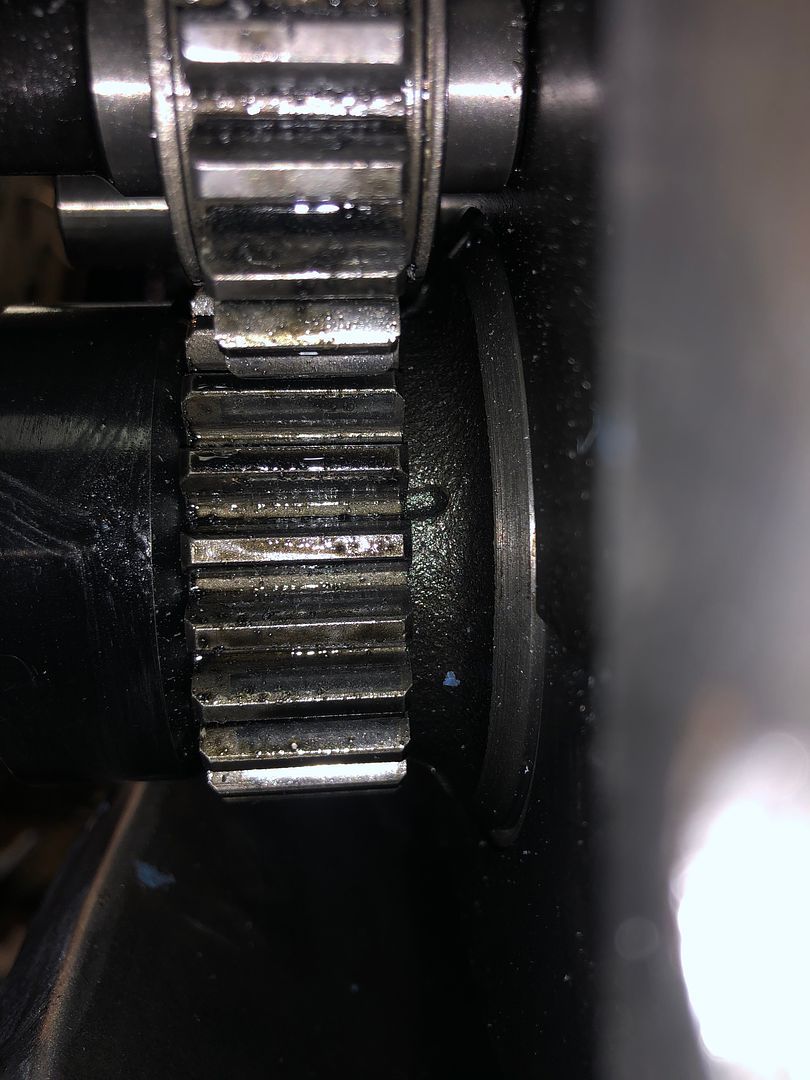

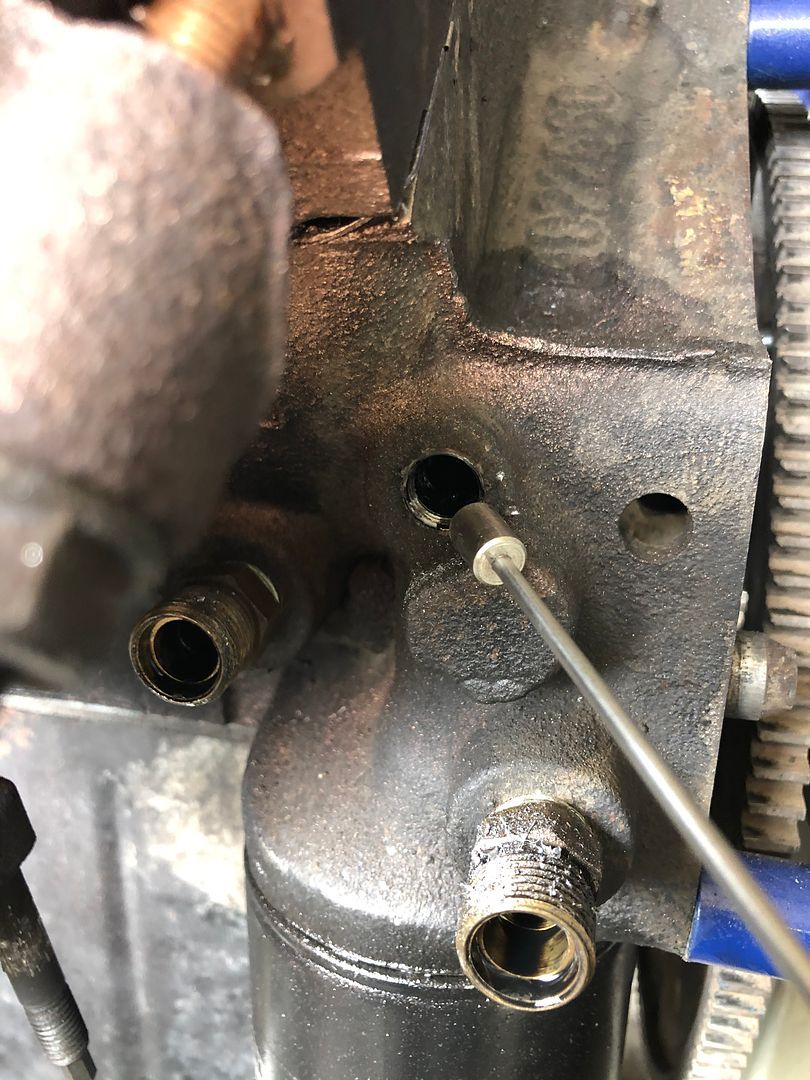

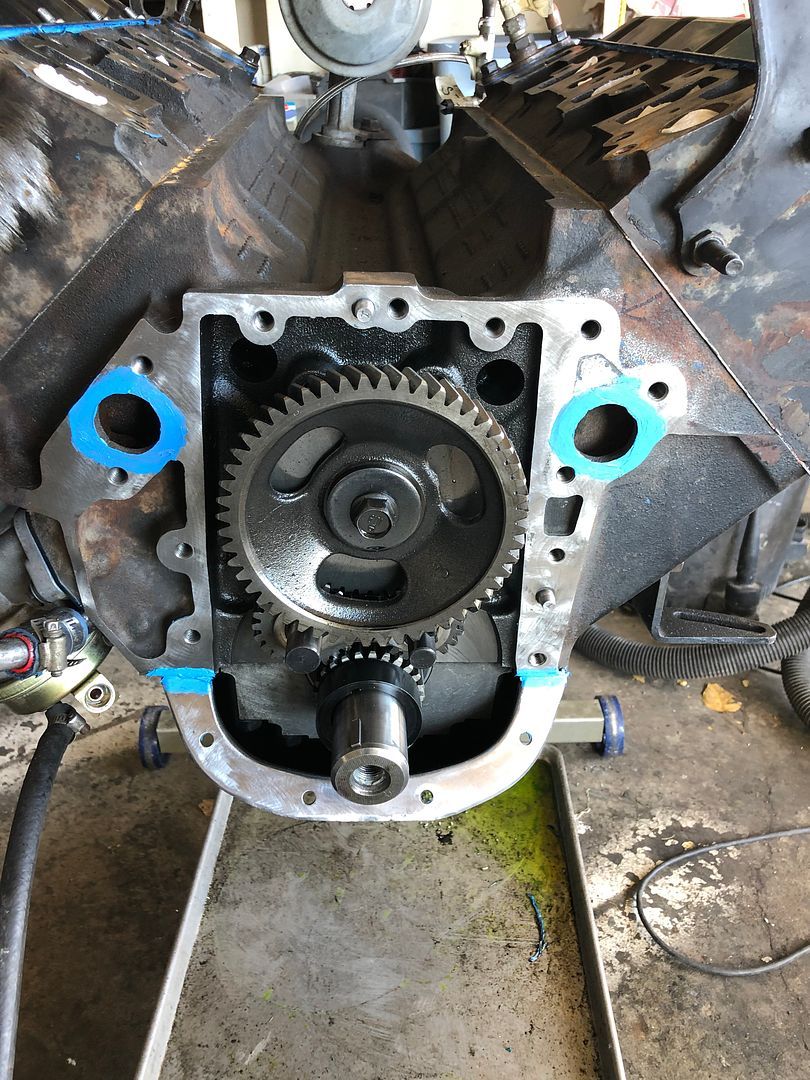

With the small wire wheel I cleaned every hole until all material was out of the threads. Taking note of which holes went all the way threw to the coolant ports.

Using the shop vac and bigger wire brush, I then cleaned the excessive gasket material from the coolant holes.

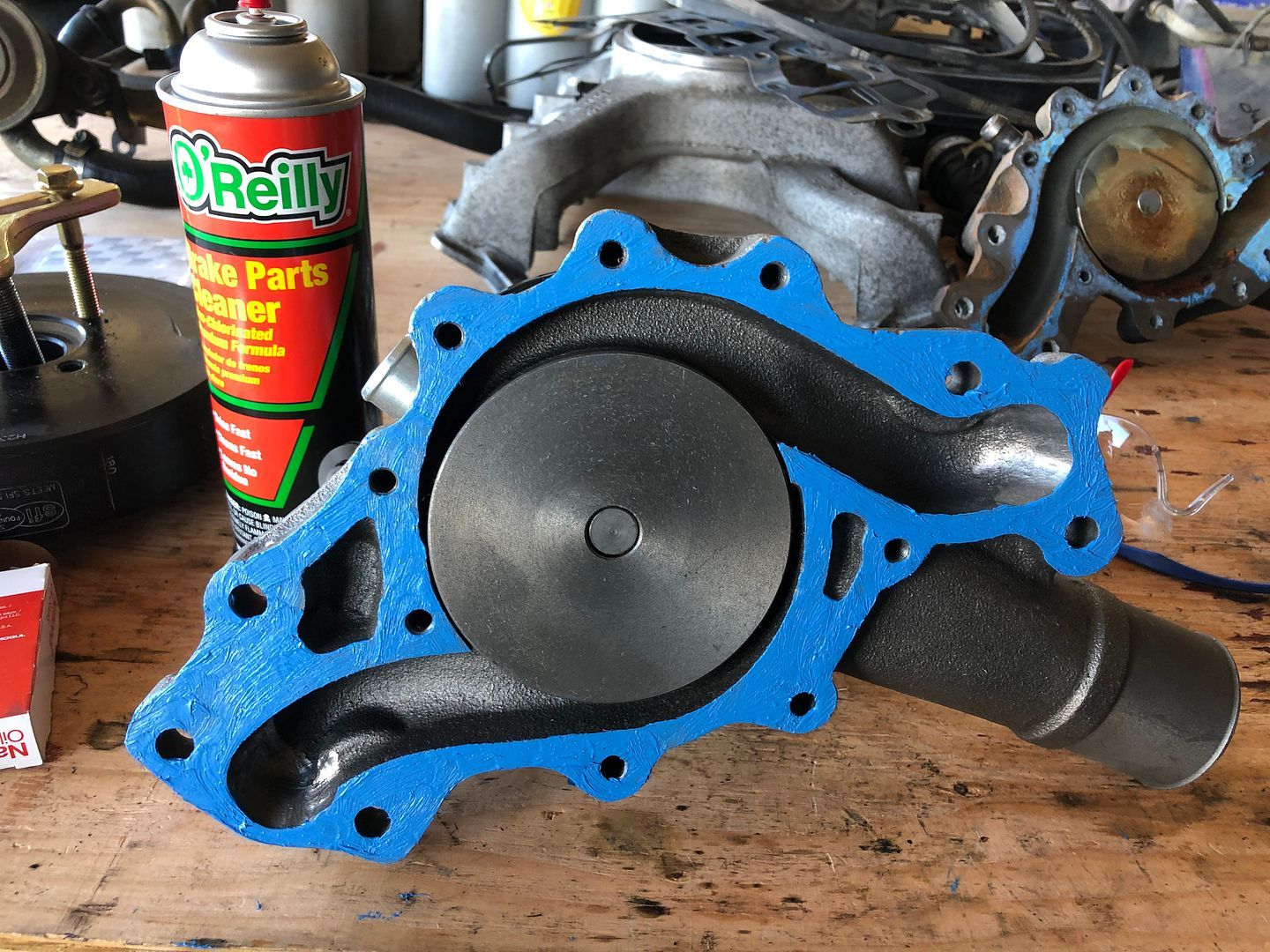

Then wiped away all oils, dirt and material with a paper towel soaked in brake cleaner.

Reply With Quote

Reply With Quote