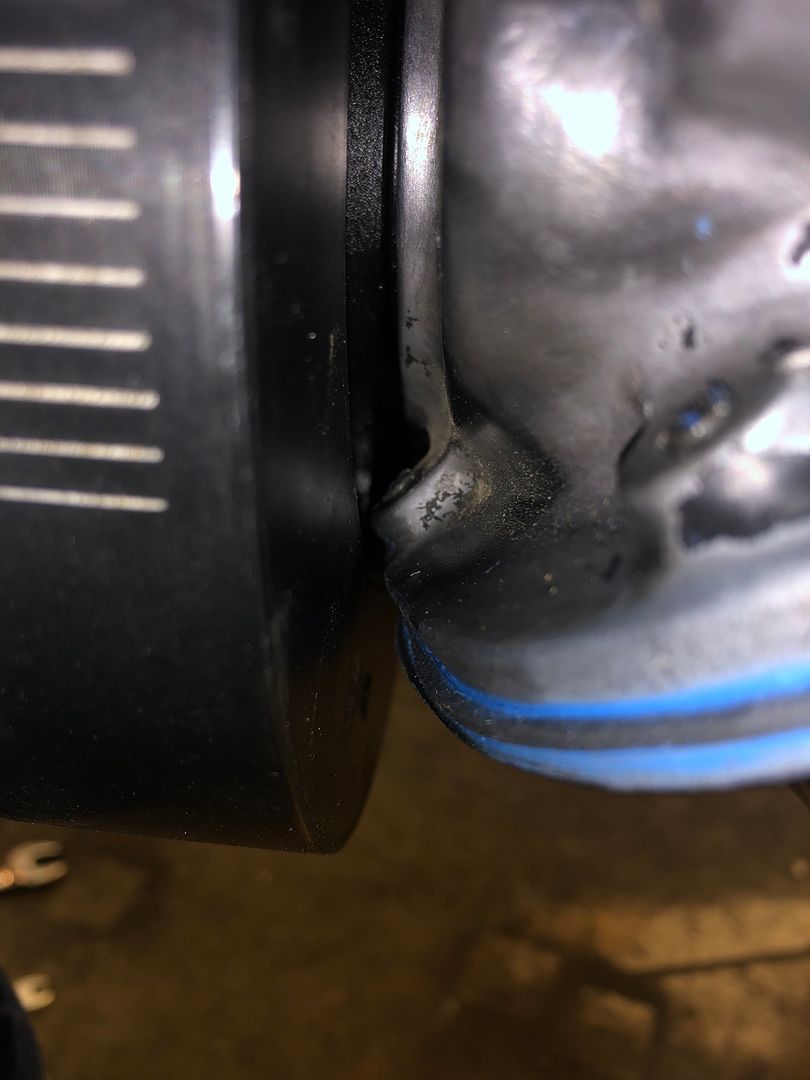

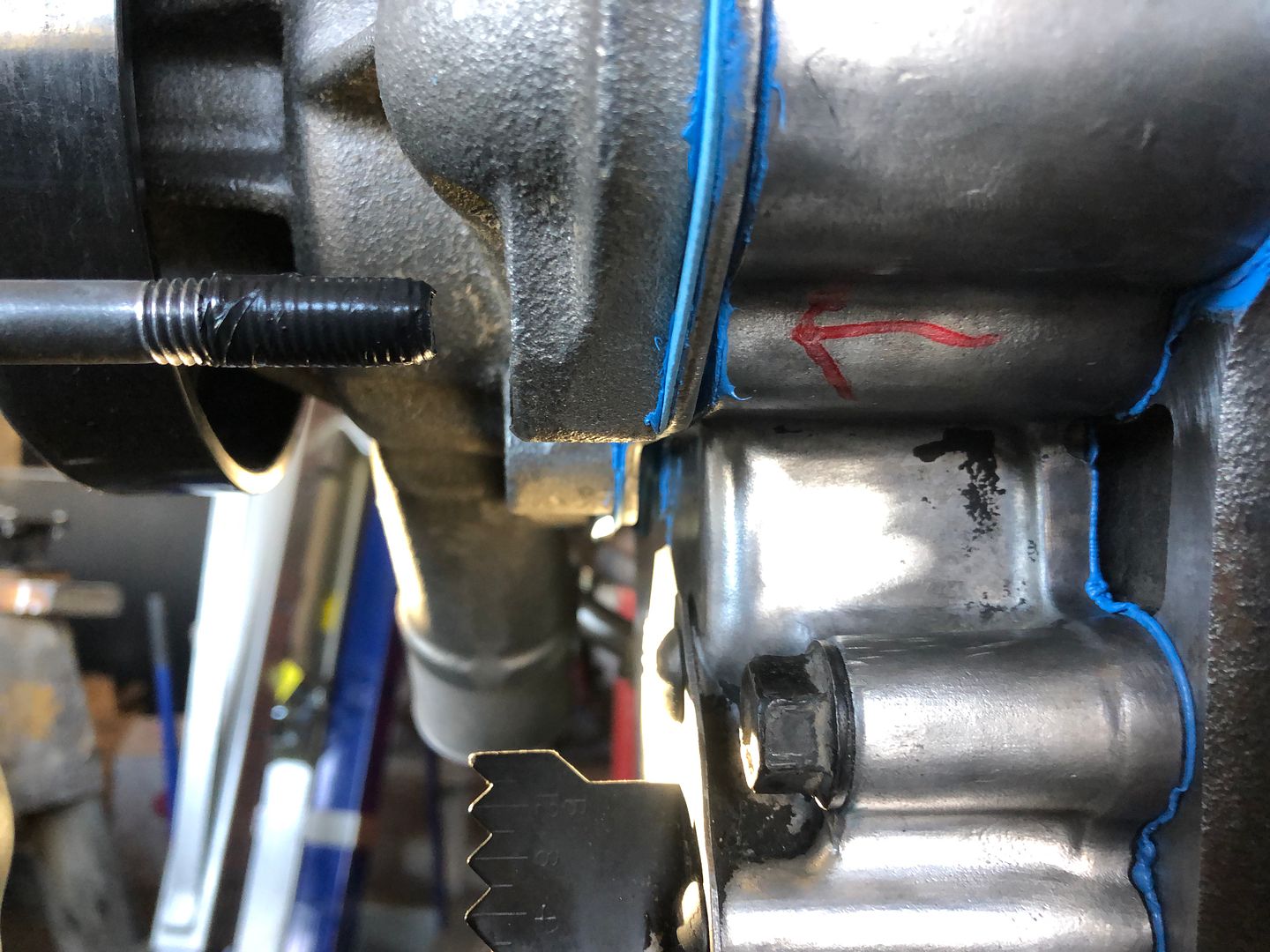

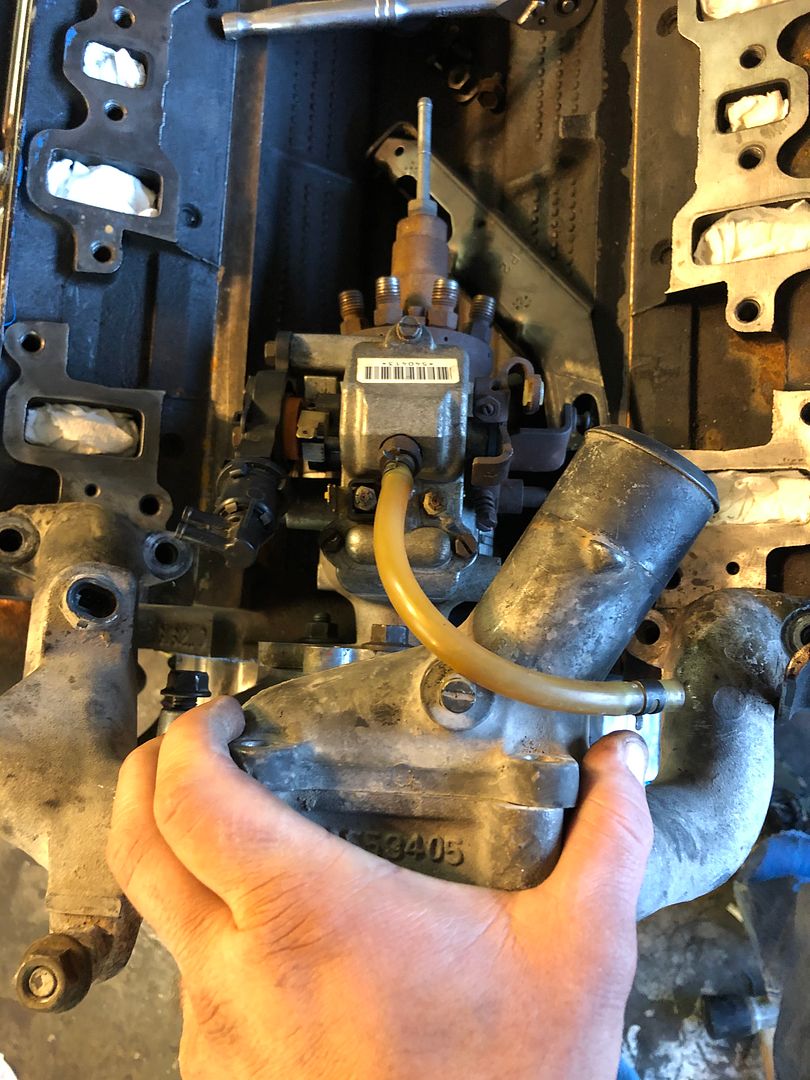

I have used this method of finger painting many times! It is a very thin layer of RTV and has proven time and time and again that it works! I never had any leaks... Ever.

This method really helps fill in the imperfections and pitting. Some may disapprove but IDC.

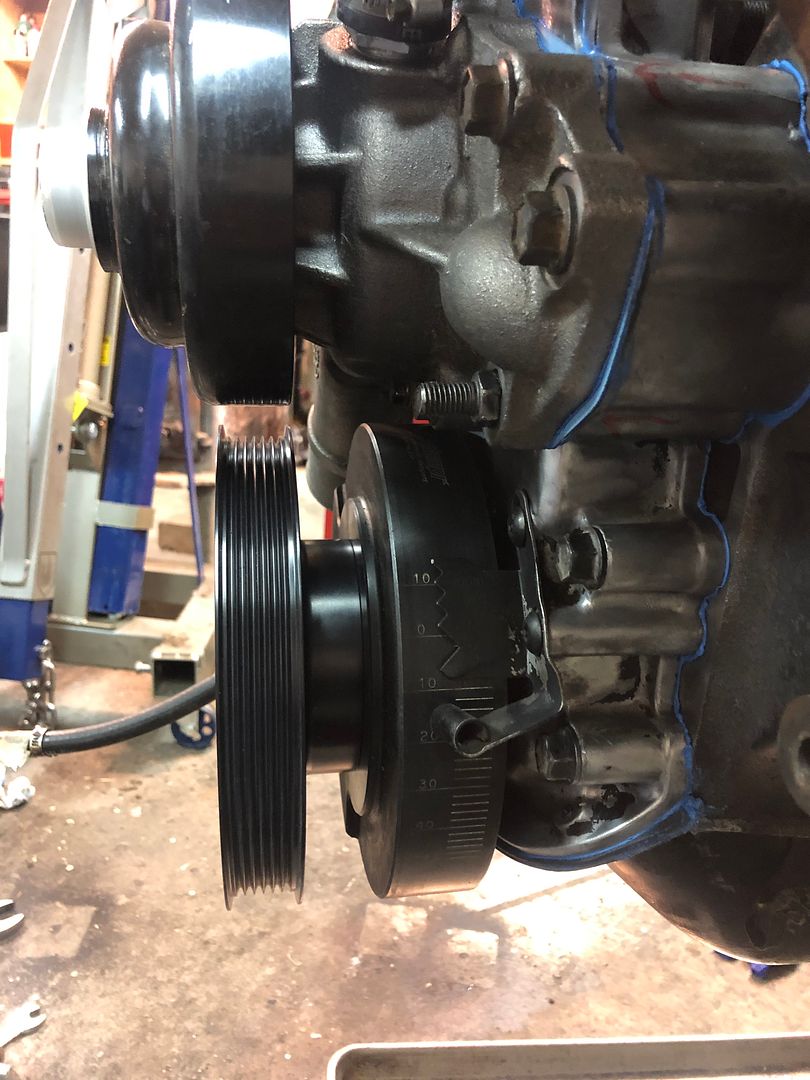

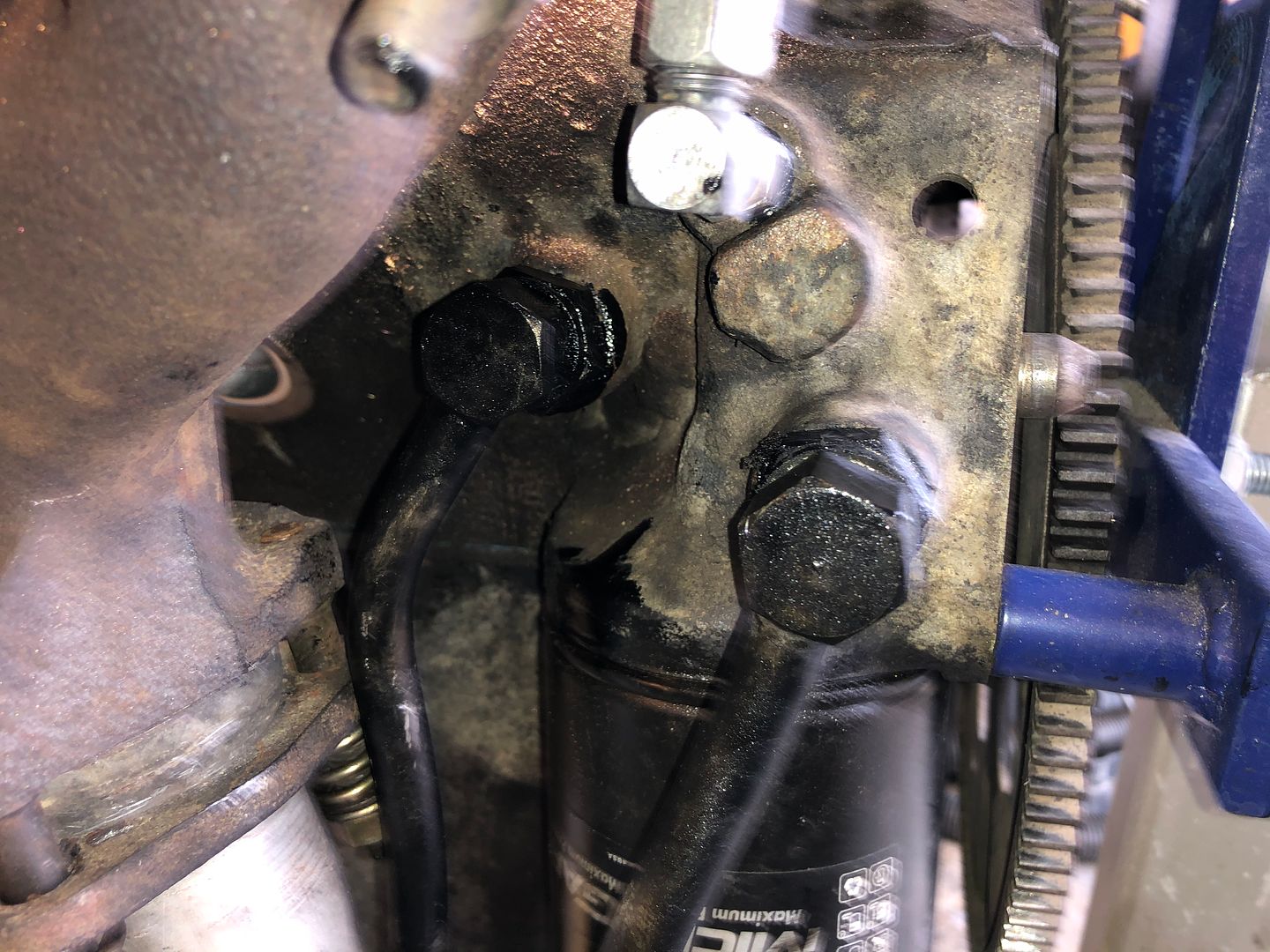

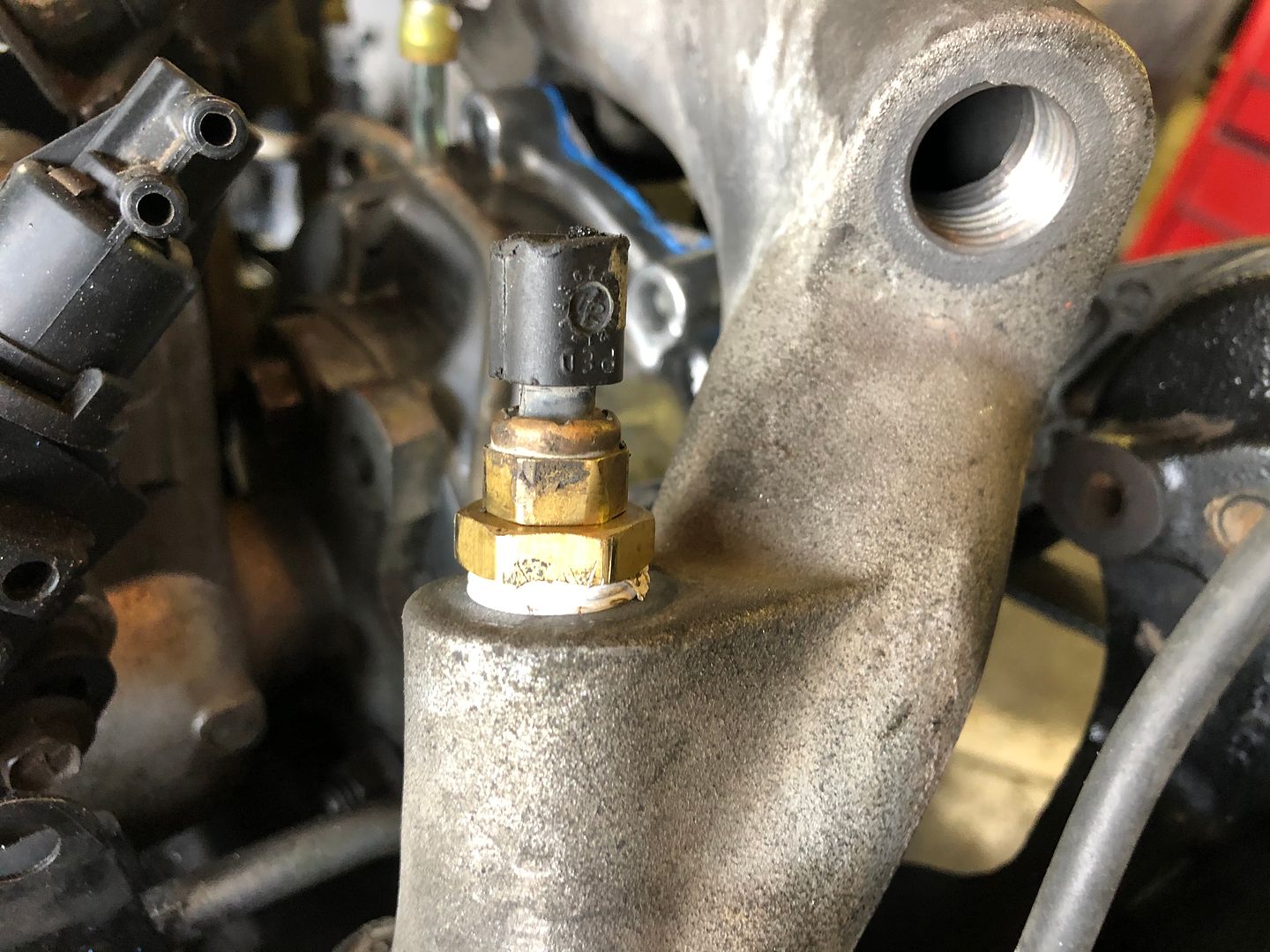

When putting on the pump I put Optimum black on these 2 bolt holes to prevent leaks from the threads.

And Optimum Black on these two 13mm bolts under the water pump.

Torquing the top 13mm bolts to 21 foot pounds and 31 foot pounds on the rest.

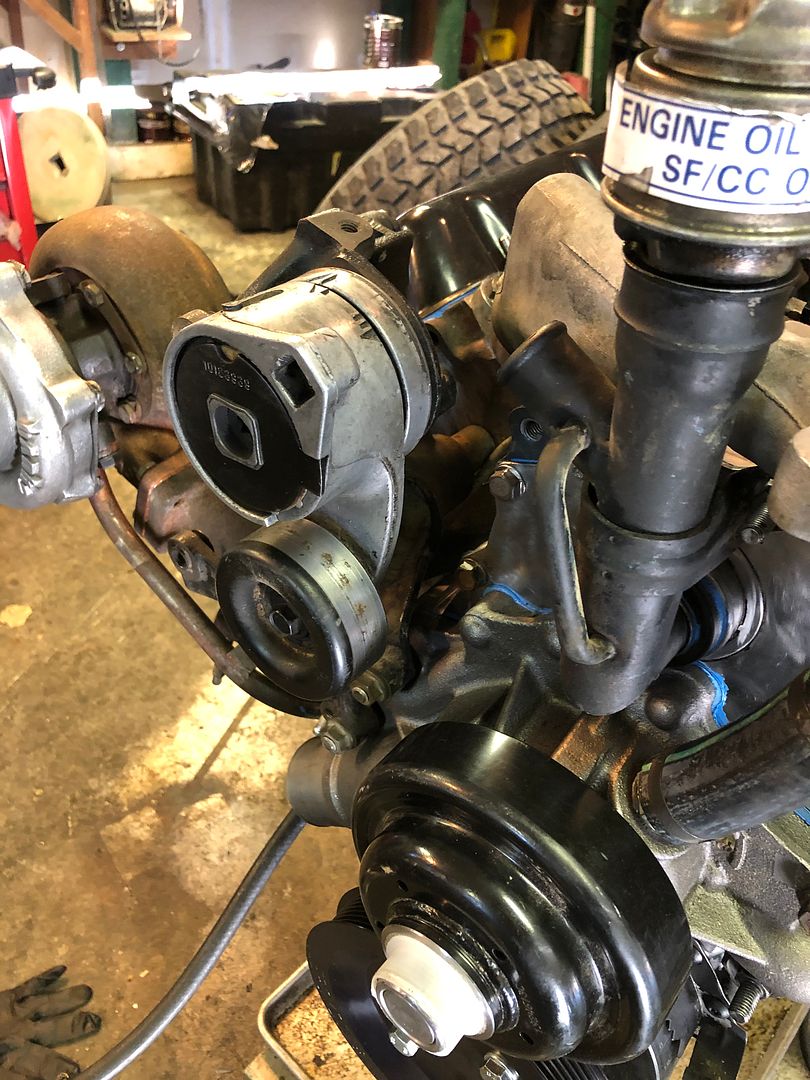

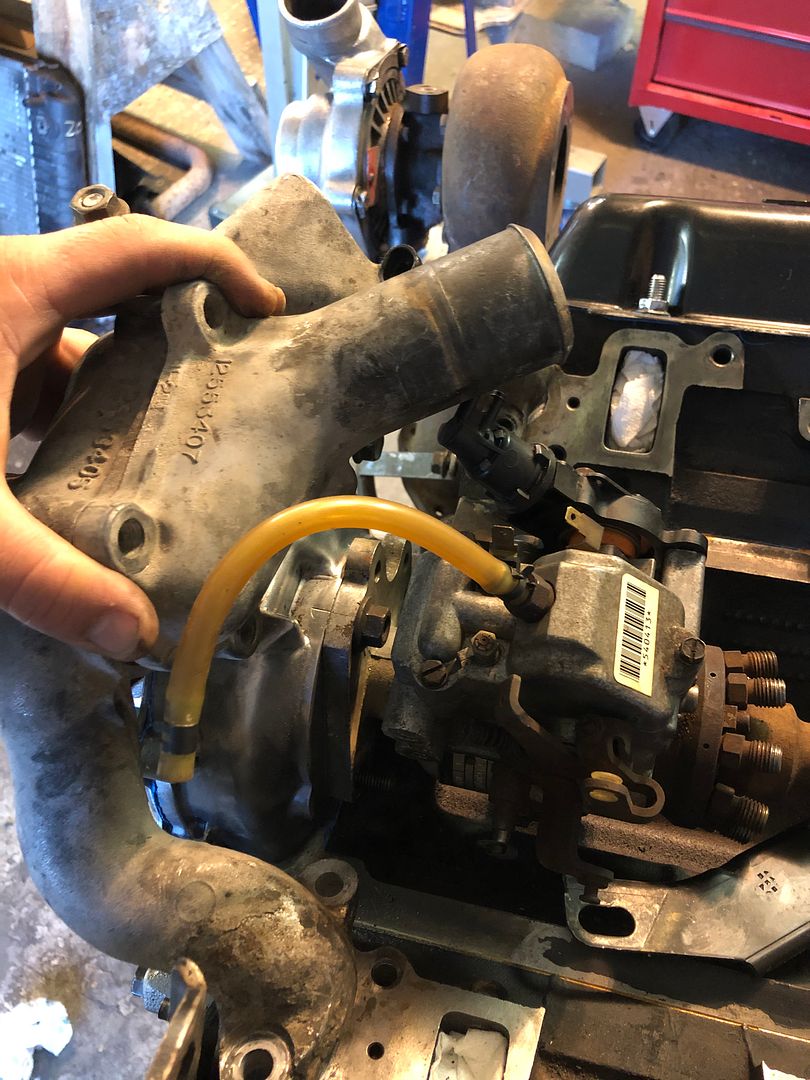

She is on!

Reply With Quote

Reply With Quote

.HEIC)

.HEIC)

.HEIC)

.HEIC)

.HEIC)

.HEIC)

.HEIC)