Hey folks, This is just the beginning to a whole bunch of things I will be doing for the 6.2l burb.

The idea is not new, but the way to get there is.

Negative pressure (a vacuum) in the crank case provides better sealing for the rings and decreases oil leaks. It can also improve gas mileage by reducing pumping losses from the bottom half of the engine. OEM manufactures know this, and they have the fancy pcv (positive crankcase ventilation) which uses check valves and manifold vacuum to draw fresh air through the crankcase and plumbs it back into the intake tract. It can also decrease emissions. While that system has been shown to work wonders, we cannot have that luxury... we don't have manifold vacuum. The solution for our engines was the pesky CDR valve, which only works (well) when there is a restriction between the manifold and air filter causing a slight amount of vacuum. But that seems to me like a crappy solution to a problem. Especially in an engine with high compression, loose tolerances, and some are even faced with forced induction to add to the issue.

I come from the modern age of performance vehicles and new ideas are brewed every day by folks on forums everywhere. One thing I came across was from a buddy of mine telling me how his dipstick was blowing out and shooting oil everywhere on his Grand National's pretty engine bay. The cause was too much blow by at 22lbs of boost. Another member from the Turbobuick.com forum used an electric smog pump from an lt1 Camaro to pull a vacuum on his crankcase, providing a sufficient route for excess gas to be evacuated. The thread can be seen here.... http://www.turbobuick.com/forums/gen...-pump-how.html

With this in the back of my mind, I discovered oil leaks on my truck, pulled the oil cap and realized that there was a lot of blow by going on and my CDR valve wasn't doing its job. Ok, time to apply what I've seen else where....

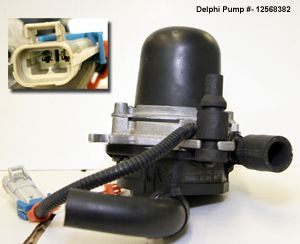

First thing to tackle was the smog pump its self. Ive gone through 3 of these now. The first one was blown when I got it. I disassemble it, discovered it was full of rust, tried to rebuild it, but failed. it was just too beat up. I got another one, that worked for a few days on a prototype setup. It eventually filled with oil in the motor housing and then met its maker when it fell from its bracket. One of the leads was torn from the motor brush. Again trying to fix it, I didn't succeed. So I went on a search for a new version that is possibly more stout. I discovered that the newer LS1 Camaro's and 'Vette's had a newer pump. Then I crossed the part numbers with other makes and models, and sure enough, the newer style of smog pump comes on tons of gm vehicles. A trip to the salvage yard, $20, and 45 mins of scouring the yard lands me with one new style pump from a Chevy Malibu and an older style from a 96 Monte Carlo. The newer one is what I used here in the pics. Its completely sealed off from the impeller and a really good design. This is what you should be hunting for.

The next step was to keep oil and moisture from getting to the smog pump. An effective oil catch can was needed. I bought one on ebay for $26. It was tiny, and a huge restriction on the whole system. not to mention very cheaply made. It will become my new coolant catch can tomorrow. Money and time wasted.

I looked for something that would work, and I found many things, but it would have cost a fortune to get things that looked like they were sufficient. My solution was good ole Home Depot. Since this won't ever see high temps or extremely caustic chemicals, I chose PVC. (not to mention I am in an apt and cant really weld here, so something cheap and user friendly was in mind) I used the following

1 four inch pipe coupler $1.13

2 four inch pipe caps $2.88

2 four inch no hub rubber coupling $10.84

4 3/4in, 90 degree plastic bend combo (barb to threads) $3.84

2 3/4in PVC couplers $1.46

Black RTV $4.79

steel wool 'Brillo' pad $ FREE (from work)

I drilled the holes with a pocket multi-tool, sealed things with rtv. the pictures will really explain the whole construction.

The Brillo pad is used as a baffle/oil trap

The next step was getting it into the truck. Now the wiring for the pump should really be set up through a relay, because I believe its more than 20 amps to get it going. I used the only 12v relay I could find from Pep Boys. I think it was for a foglight setup. I used the positive from the IP shut off switch as the switching power. (later I might look into using a LM555 timer and transistor to use PWM to drive the motor....well see)

I moved the coolant reserve tank and held it in place by using one of its original bolt holes in the fender and kind of cocked it downwards...it works, but like I said earlier, Its getting replaced tomorrow anyway.

I used an exhaust hanger bracket clamped to the catch can and bolted down to where I believe the jack or something used to be held.

I then squeezed the back of the pump to fit into the cut out in the fender support. Its nice and snug, but a better mounting fixture with rubber isolation is really needed here. (this pump is a powerful sucker, it makes some real noise)

The plumbing was easy, I used a 3/4 piece of heater hose to go from the CDR outlet on the oil filler neck to the inlet of the catch can (that's the one with the 90* piece on the bottom of the catch can lid). Then I used the factory piece that was already attached to the smog pump to go from the outlet of the catch can to the inlet of the smog pump. The outlet of the smog pump was sent straight back to the intake.

Here are pictures...

I suffer from CLSA, there is no end in sight....I just Can't Leave Sh!t Alone!!!!

I suffer from CLSA, there is no end in sight....I just Can't Leave Sh!t Alone!!!!

Reply With Quote

Reply With Quote

.I was looking for a way to keep oil fumes from entering my aftercooler,i came across a crankcase filter made by racor.They are made for diesels in boats mainly.I was hoping that one would work on my engine.Has anyone here tried one on their trucks or had any experiance with one?

.I was looking for a way to keep oil fumes from entering my aftercooler,i came across a crankcase filter made by racor.They are made for diesels in boats mainly.I was hoping that one would work on my engine.Has anyone here tried one on their trucks or had any experiance with one?